E-Glass Assembled Panel Roving

PERFORMANCE ATTRIBUTES

● IMPROVE EFFICIENCY

Low fuzz combined with easy chopping, flat lay down and uniform dispersion saves time.

● REDUCE THE COST

Higher glass loading with optimal resin consumption reduces the amount of expensive resin required.

● GREAT PERFORMANCE

Good mechanical properties, great surface quality, excellent conform-ability, doesn't trap air, low spring back.

● FAST WET-OUT

Designed to provide optimal performance for spray-up applications where fast wet-out speed is preferred; great performance in various types of part complexities.

| Item | Linear Density | Resin Compatibility | Features | Application |

| GC-01A | 2400, 4800 | UP | low static, moderate wet out, excellent dispersion | translucent and opaque panels |

| GC-02A | 2400, 4800 | UP | extremely fast wet-out, superior transparency | high transparency panel |

| GC-03A | 2400, 4800 | UP | low static, fast wet out, no white fiber | general purpose |

| GC-04A | 2400 | UP | good dispersion, good anti-static property, excellent wet-out | transparent panels |

Contact Us for More Specifications and Pricing

| Linear Density (%) | Moisture Content (%) | Size Content (%) | Stiffness (mm) |

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ±5 | ≤0.15 | 0.60±0.15 | 115±20 |

| Type of Glass | E |

| Assembled Roving | R |

| Filament Diameter (μm) | 12, 13 |

| Linear Density(tex) | 2400, 4800 |

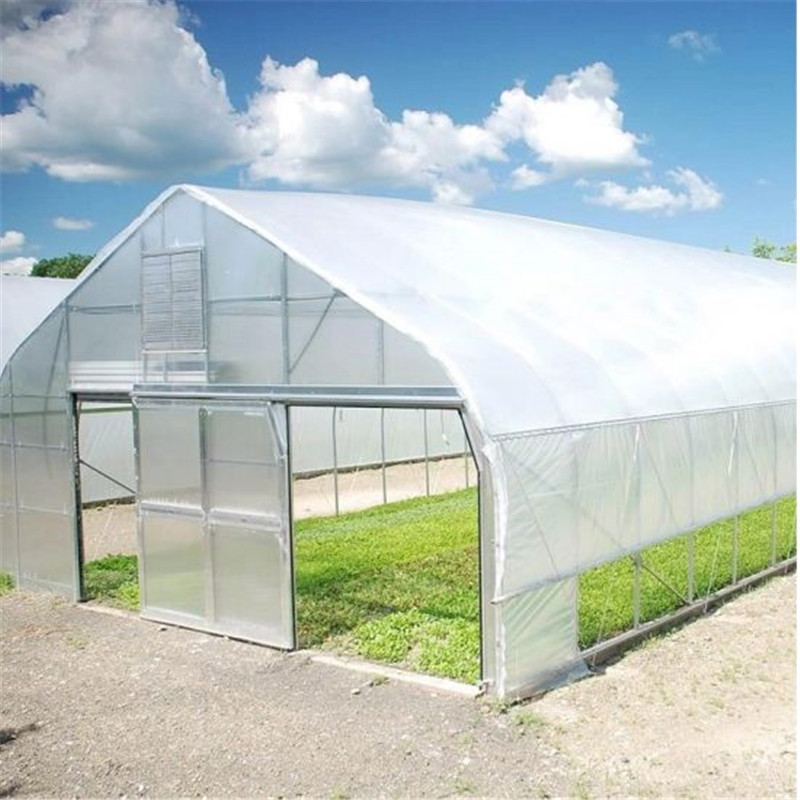

SUCCESSFUL CASE

Assembled rovings with a tex between 1200 and 2400 are usually used for the production of transparent composite panels. This range of tek weights provides the right balance between fabric stiffness and drape. The stiffness of the fabric determines the stiffness level of the panel's composite laminate. If the assembled roving is stiffer, the composite structure will be stronger and vice versa.

For larger transparent panels with high aspect ratios, higher basis weight assembled rovings may be used to provide increased stiffness and strength. This helps reduce deformation and the possibility of damage from impact. Furthermore, in addition to selecting the correct panel thickness, the use of higher tex assembled rovings will allow manufacturers to design larger clear composite panels as it helps to increase the structural integrity of the panels.

The volume fraction of fibers is also considered in determining the appropriate tegram weight of assembled rovings for a particular application of a transparent composite panel. Fiber volume fraction refers to the percentage of the total panel volume occupied by fibers. A higher volume fraction means more fibers and less resin in the composite structure, which increases the overall strength and stiffness of the panel.

PRODUCTION WORKSHOP

APPLICATION

It can be used to manufacture lighting boards in building & construction industry.

24-HOUR SERVICE

Can't find what you're looking for?

Don't worry, feel free to contact us!

In addition to the products we offer ourselves, we have other professionals who are responsible for finding other resources for you.

Save your time, effort and cost!

DEMAND FOR SUSTAINABLESOLUTIONS

Building & Construction

Improved Strength-to-Weight Ratio of Composites Enables Internal and External Building Applications.

Infrastructure

Legacy of Material Conversions Product Innovation and Integration