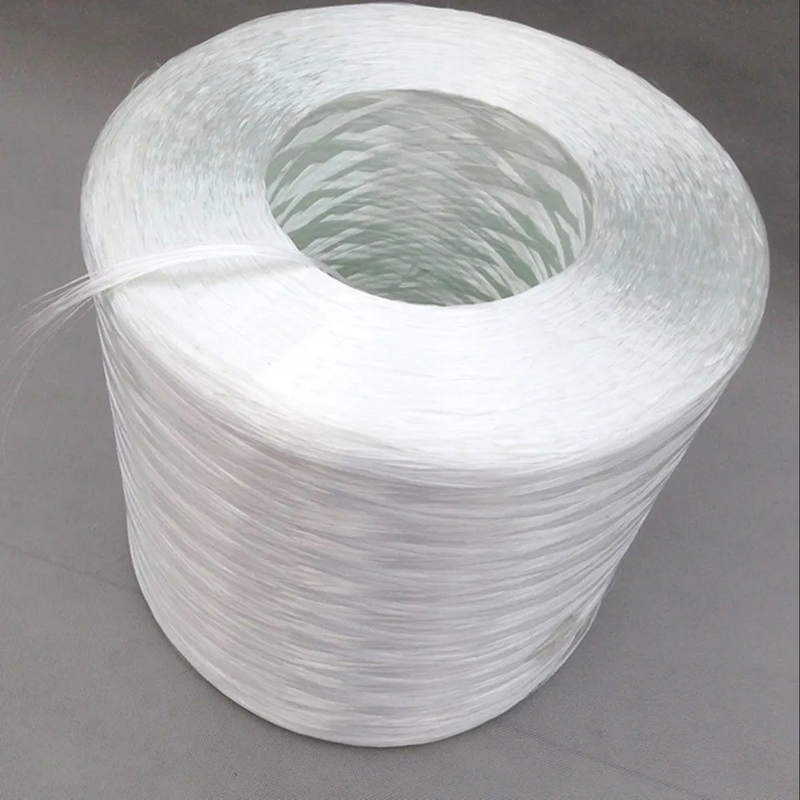

E-Glass Assembled Roving For SMC

PRODUCT ADVANTAGES

● HIGH EFFICIENCY

Thanks to the fast wetting and uniform distribution of each filament, GRECHO assembled roving ensures a high output, saving time and labor costs.

● SUPERIOR STRENGTH

GRECHO Assembled rovings have higher tensile strength, modulus, and resistance to deformation and breakage than chopped strands, ensuring a durable finished product.

● GOOD PROCESSABILITY

GRECHO Roving is suitable for various SMC processes, providing good formability and surface quality for finished products.

● ECO-FRIENDLY

GRECHO E-glass fibers are environmentally friendly and recyclable, allowing for more sustainable manufacturing practices.

PRODUCT DETAILS

|

Item |

Linear Density |

Resin Compatibility |

Features |

Application |

|

GCSMC-01A |

2400, 4392 |

UP, VE |

For general pigmentable SMC products |

truck parts, water tanks, door sheet and electrical parts |

|

GCSMC-02A |

2400, 4392 |

UP, VE |

High surface quality, low combustible content |

ceiling tiles, door sheet |

|

GCSMC-03A |

2400, 4392 |

UP, VE |

Excellent hydrolysis resistance |

bathtub |

|

GCSMC-04A |

2400, 4392 |

UP, VE |

High surface quality, high combustible content |

bathroom equipment |

|

GCSMC-05A |

2400, 4392 |

UP, VE |

Good chopped ability, excellent dispersion, low static |

automotive bumper and headliner |

To View More Specifications Please Contact Us

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.25±0.15 |

160±20 |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter (μm) |

13, 14 |

| Linear Density (tex) |

2400, 4392 |

PRODUCT SELECTION ADVICE

Assembled rovings for SMC are available in various sizes depending on the application. Here are some common sizes and their associated applications:

- 2400 tex - Assembled rovings of this size are typically used in the manufacture of automotive parts such as body panels, hoods and doors. It is also suitable for making water tanks and utensils.

- 3600 tex - Assembled rovings of this size are commonly used in the manufacture of pipes, storage tanks and other industrial products. It is also suitable for the production of large structural parts such as panels.

- 4800 tex - Assembled rovings of this size are commonly used in the manufacture of high strength pipes and tanks. It is also suitable for the production of highly rigid structural parts.

- 6000 tex - Assembled rovings of this size are typically used in the manufacture of large structural components such as wind turbine blades or ship hulls.

It is important to note that the proper size of aggregate roving for a particular application will depend on several factors including the desired strength, stiffness and surface finish of the final product.

PRODUCTION WORKSHOP

PACKAGING

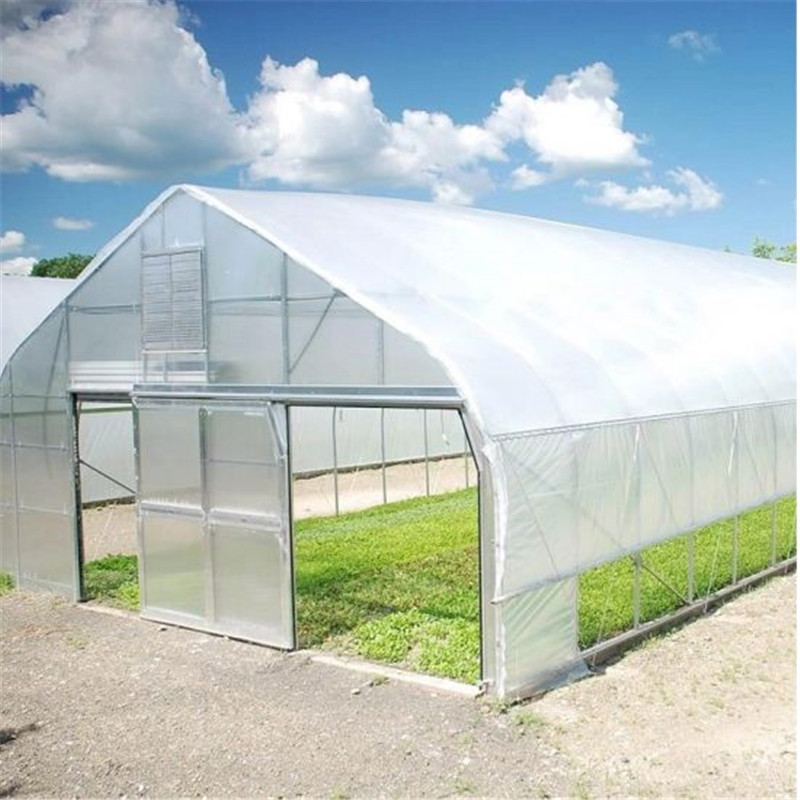

APPLICATION

E-Glass assembled rovings for SMC are ideal for sheet forming applications including automotive components, appliances, bathroom fixtures and other high quality fiberglass products.

WHY CHOOSE US?

RAW MATERIALS:

The raw materials used in our products come from partnerships with manufacturers of internationally recognized brands.

PRODUCTION LINES:

Machines and equipment are regularly maintained to ensure efficient, consistent production.

QUALITY CONTROL:

Quality control is a top priority for GREHO and strict testing procedures are in place.

LOGISTICS:

Reliable logistics and packaging are in place to ensure that products arrive at their final destination in the same condition as when they left the factory.

GRECHO Stories

At GRECHO, our focus is on customer satisfaction and providing the highest quality products in the fiberglass industry.

Our products are produced in excellent factories in China, using the most advanced equipment, including electronic drive machines, computer-controlled fiber forming equipment, and high-speed packaging machines, to ensure stable product quality.

Our quality control system complies with ISO 9001 and ISO 14001 standards.

OUR HONOR

Click Here for more stories about GRECHO and Our Partners

DEMAND FOR SUSTAINABLESOLUTIONS

Building & Construction

Improved Strength-to-Weight Ratio of Composites Enables Internal and External Building Applications.

Infrastructure

Legacy of Material Conversions Product Innovation and Integration

TECHNICAL SUPPORT

GRECHO also offers Technical Support, which focuses on

trouble shooting and increased productivity for our customers.