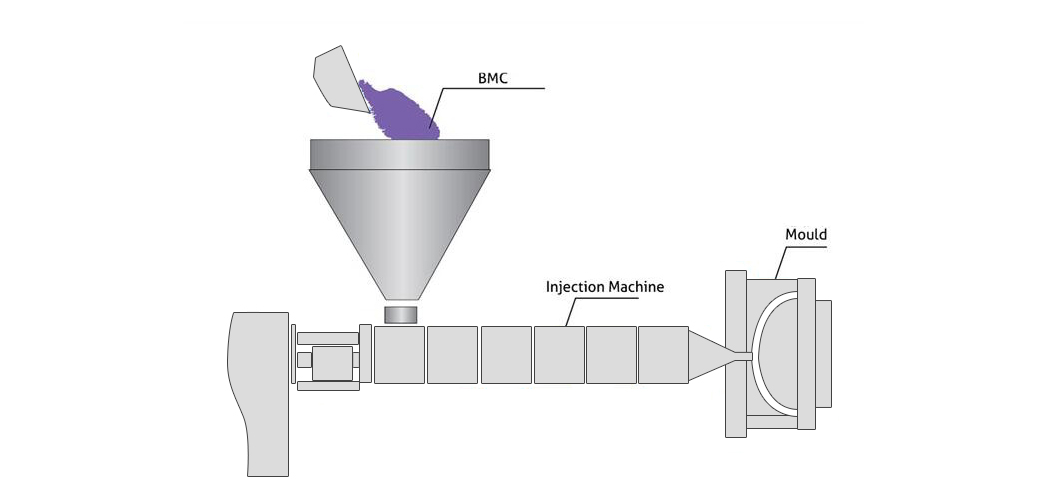

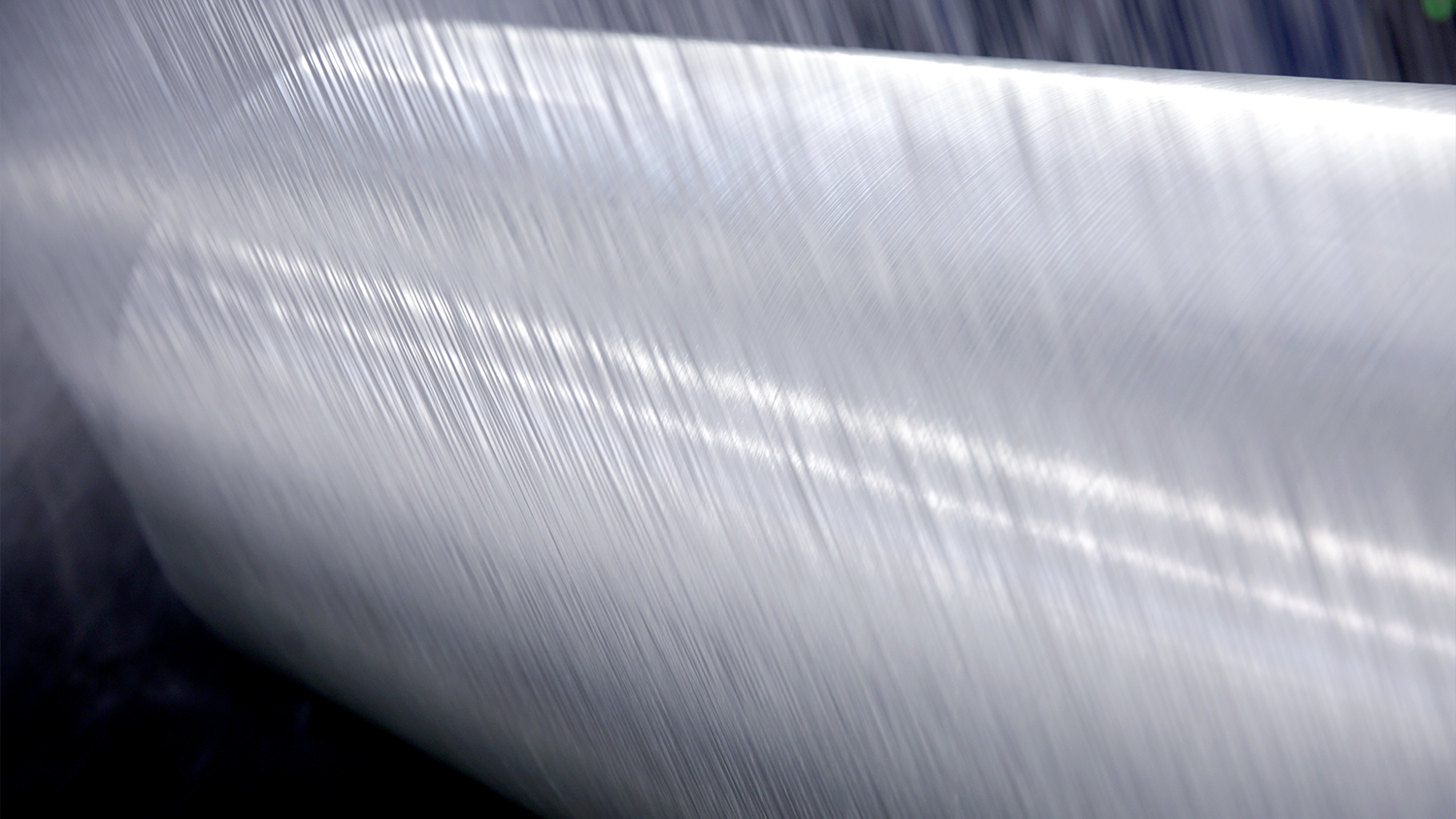

Chopped Strands For BMC

PERFORMANCE ATTRIBUTES

COST EFFICIENT

STABLE STRUCTURE

FAST AND UNIFORM DISTRIBUTION IN RESINS

NOT EASY TO CORRODE

● COST EFFICIENT

Suitable for compounding with resin as a reinforcement material for car, train and ship shells

● STABLE STRUCTURE

Improve high temperature stability, low temperature crack resistance, and extend road surface life

● FAST AND UNIFORM DISTRIBUTION IN RESINS

After the cement concrete/mortar anti-cracking and anti-seepage fiber is added to the concrete, it exhibits good dispersibility, strong hold with the cement concrete matrix, and obvious anti-cracking, improved impermeability, frost resistance, impact resistance

● NOT EASY TO CORRODE

It will not be affected under the conditions of strong acid, strong alkali, etc

|

Item No. |

Chop Length,mm |

Resin Compatibility |

Features |

|

GC-01 |

3,4.5,6,12,25 |

UP |

Good Flowability,High strand integrity |

|

GC-02 |

3,4.5,6,12,25 |

UP,EP,PF |

Low static,Good flowability,High strand integrity |

|

GC-03 |

3,4.5,6 |

PF |

Good flowability, High strand integrity,High strength |

|

GC-04C |

3,4.5,6,12,18 |

UP,EP,PF |

Consistent chopped strands, even dispersion during stirring, high retention of chop length, high strengh of composite products, possible use for composites of high color quality. |

|

Type of Glass |

E |

|

Chopped Strands |

CS |

|

Filament Diameter,μm |

13 |

|

Chop Length,mm |

3,4.5,6,12,18,25 |

|

Sizing Code |

BH-BMC |

|

Filament Diameter (%) |

Moisture Content (%) |

LOI Content (%) |

Chop length (mm) |

|

ISO1888 |

ISO3344 |

ISO1887 |

Q/BH J0361 |

|

±10 |

±10 |

0.85±0.15 |

±1.0 |

ADVANTAGE

1. GRECHO high quality alkali-free glass fiber not only has the advantages of traditional alkali-free glass, but also provides technological breakthroughs in strength, modulus, corrosion resistance, high temperature resistance, etc., able to meet the demand of the market.

2. Specially designed for reinforcement with unsaturated polyester, epoxy and phenolic resins. Its unique sizing formula gives the product excellent mechanical properties.

APPLICATION

Widely used in transportation, construction, electronics,chemical industry and light industry. Such as the automotive parts, insulator and switch boxes.

TECHNICAL SUPPORT

GRECHO also offers Technical Support, which focuses on

trouble shooting and increased productivity for our customers.